Hand Tool Headlines

The Woodworking Blogs Aggregator

“Glory to God in the highest heaven, and on earth peace to those on whom his favor rests.” - Luke 2:14

Norse Woodsmith Blog Feeds

Mile's desk pt II.........

|

| making quark |

Before I went to the shop I made a batch of quark for the blue milk paint. I will make the 2nd batch of quark for the red paint after I get this one done.

|

| hmm...... |

The open knot on this face (the down side) is almost an inch and a half at the widest and 3/4" at its narrowest. Undecided about whether or not to fill it in on this side. It is on the underside and won't be seen - the drawers will cover it.

|

| #4 1/2 with a 55° frog |

The proud was not quite a 16th and I couldn't flush it entirely with this plane.

|

| #80 |

Got it almost flushed with the #80 within a frog hair. I had problems with the #80 chattering a lot more than I expected.

|

| got a hump |

I got all 3 of the glue joints dead flush and it is flat on the opposite diagonal and there was a hump this way. The hump is right on the swirling bullseye grain. The 4 1/2" didn't have any problems planing this area without tearing out.

|

| toothing iron |

This is the third time I've used this iron. I've had it for almost 20 years. Using the jack so I could feather out the hump area.

|

| almost |

This wasn't as awkward to do as I anticipated it being. I have two stops on the workbench, one at the end and another on the left side. I pulled the planes toward me while standing at the end of the workbench. It took a while before the hump got flattened.

|

| love the depth of the black color |

I stuffed the knot hole with a bunch of cherry shavings so I didn't have to use gallons of epoxy to fill it.

|

| 2nd application |

About 20 minutes after I initially filled it I put some more on. One spot had dipped down below the top. Fingers crossed that come tomorrow it will be still over filled and not sunk down.

|

| quark is 99% done |

I think I did better on this batch then I did with the previous ones. I know I did better with rinsing until it ran clear. I put this in the refrigerator to dry out and drain any remaining liquid.

|

| hmm....... |

Got this yesterday from Amazon - 10 feet of plumber's chain. I wasn't sure here if it will work as a chain stay for the miniature chest.

|

| not smooth sailing |

As I smoothed one set of chatter marks, I made a new set. Tried all the tricks I knew but without success.

|

| stubborn spot |

I had smoothed this area of chatter marks but I had to take one more swipe. My reward? Three more lines of chatter. This one area was an absolute nightmare trying to smooth out.

|

| the smoothing trio |

The scraper plane (Stanley #112) was the only one that didn't chatter. The Stanley veneer scraper (#12) chattered a couple of times. The #80 was the worse. The scraping planes left behind a glass smooth surface, much better than the #80 did.

|

| ornery spot |

This area was a PITA to smooth out. It didn't tear out exactly but certain strokes left a fuzzy line.

|

| been a while |

I thought I had two #112s but it is two #12s. The last time I used these was when I made the cradle for Miles. Hard to believe but that was almost ten years ago. BTW I only have one Stanley scraper iron in these three. After searching I finally bought replacement irons from Hock. I bought two toothed irons from Kunz - I emailed the US representative and bought two from him. Had to wait until Kunz in Germany made a batch of them. The fit with both the Hock and Kunz irons was perfect.

|

| it works |

Setting the hinges using super glue. Two dabs on each hinge with a little weight for 10 minutes holds the hinges in place long enough to get screws started.

|

| underside |

No leaks. The blue tape is still down tight and it isn't bulging neither.

|

| two screws |

Got two screws in each hinge. Unfortunately for me, I didn't have any flat head, slotted, #6 screws in the length I wanted. I went to ACE but two things stopped me from buying screws there (and having an involuntary bowel movement). They had brass screws in the size I wanted but they were phillips head (a no no for me) and the cost took my breath away. 50 screws in 1/2" was $17 and the 3/4" size was $19. I don't remember screws costing this much the last I bought a pkg of 50.

I ended up buying the screws from McMaster-Carr. Bought two boxes of 100 each and the price was almost as much as the ACE pkg of 50 screws cost. I'll have to start watch vids on making without any fasteners like screws and nails.

|

| hardware is done |

Got the chain stay installed without any hiccups. The hinges are all set to be reinstalled once the paint is done.

|

| shellac time |

Got 4 coats on the interior of the chest (done) and two on the back doohickey thing. 3-4 more on it and it will be done.

accidental woodworker

25 Years of Changes

Game Table. NY 1760-1790

Game Table. NY 1760-1790A recent visit to the furniture collection at the Metropolitan Museum really emphasized how profoundly furniture-making has changed since my youth - and even in the 25 years since I founded TFWW.

I grew up reading Popular Mechanics, and I imagined that I too would engage in their home improvement projects when I grew up. Build a den; build a media center; build a kitchen cabinet; stuff like that. On top of that, the magazine offered tons of material on building reproductions of colonial style furniture, usually with the latest power tools. Home repairs, like car repairs, were within the grasp of ordinary people with mainstream skills and tools. DIYing was a popular hobby and for the average guy, (and I mean guy at this point in time) practical classes in Shop class in school gave you the foundation to make things.

I also began reading Fine Woodworking in 1976. (I missed the first two issues and started with Issue No. 3.) The magazines focus on fancy techniques like wood bending and a high valuation of the craft were real eye openers for me. Fast Forward to now. The major area of business for modern cabinet makers is in architectural woodworking - re-fitting kitchens, building interiors, stores, bookcases and other millwork. The popular expectation of dressers, tables, beds, etc. is inexpensive and disposable, made by IKEA and IKEA-like companies.

Fewer people now than ever before would consider themselves amateur woodworkers. The interesting part is that the ones who are doing it are doing it to a higher standard than ever before. They are no longer constrained by the mass market. If youre going to the trouble of making a colonial style high boy, youre probably doing it because you want to dive into that kind of piece, even if that means learning how to veneer, learning how to dovetail, learning how to carve details. All sorts of wonderful skills - which is where the challenge and interest lies.

Getting back to the museum: While the Metropolitan Museum of Art has the second largest collection of American furniture in the US (after Wintertur), most of the vernacular stuff they have is in the study collection, not in the fancy exhibition halls. The period rooms almost all have fancy rich furniture - items that highlight and show off wealth rather than comfort and function. The pieces are all beautifully made with great skill, but very few things are relatable nowadays. People aren't looking for a chair with fancy decorations and inlays. They want something that conjures up the image of a traditional chair - and the vernacular stick chair world does that in spades.

For most people interested in traditional skills, the direction seems not to copy the stuff in museums, but rather focus on the kinds of vernacular furniture that frankly was too downmarket to interest bigtime furniture collecting. I'm talking about stick chairs and other folk work. People are following this path for two reasons: first, while you need much fewer tools to make a stick chair, the craft demands the same rules of design and proportion so its still a fun challenge, and second, vernacular furniture is a lot more relatable in a modern house than the fancy furniture we see in museums.

Note: the Metropolitan Museum of Art has remounted a lot of works in their American Wing. They're mounting furniture in a way that asks you to look at it closely and see the details. They're trying to create an appreciation of the design of traditional furniture, or should I say, traditional high-end furniture that has largely vanished. I think a lot of people look at the furniture in the American Wing, and say, My word! That stuff looks dated! and never look past this unrelatability to the details. (This is especially true when whole rooms are preserved.) They therefore dont enjoy or appreciate the craft that went into making fancy furniture. Of course the museum pieces were expensive luxury items. But theyre still wonderfully proportioned; theyre elegantly made; and a pleasure to examine and well. A lot of them dont fit into a modern lifestyle, i.e. a place to put your laptop, a sofa you can watch TV from (and sadly nobody these days is coming over to play games). But this doesn't mean the works aren't extremely elegant in the context of their original use - and we can still learn from them.

Note: We stock a lot of detailed, accurate measured drawings by Carlyle Lynch of early American Furniture, some fancy,some not.

We also stock "Welsh Stick Chairs" a wonderful book and we have a few copies left of The Stick Chair Journal.

For a more philosophical look at chairmaking you might want to look at "Chairmaker's Notebook" by Peter Galbert.

Miles desk...............

|

| hmm....... |

First change is with the top. This one will be about 36x24. I got four boards to choose for the top. That will be whittled down to a 3 board top. My desk top is 44x 25.

|

| maybe not |

This is the cherry bookshelf I made for Mile's desk. It looks a wee bit

too big IMO. I pictured this being used for reference or school books

(CD/DVDs too). I'll be rethinking this - I have two smaller cherry

bookshelves waiting in the wings that might look/fit better.

|

| took a while |

I went back forth with the four boards and I ended up using the one with a knot. I like how the grain flows with these three boards. The knot goes straight through the board. This face has the smaller opening with the opposite face over twice the size. I am going to fill it in with epoxy dyed with black pigment.

|

| can't dutch it |

I was thinking of covering the the knot hole with a dutchman. I didn't have any cherry off cuts with a circular grain pattern like the knot has. First option was cherry and then I thought of using walnut. Nixed both because of the grain.

|

| jointing the top boards |

This is about the only time I use my #8 Stanley - just for jointing boards for edge gluing. Checking for the edge square to the face. Used a 48" straight edge to check the edge was flat and straight.

|

| hmm...... |

There was a slight gap here due to a hump. It took a few plane and check steps before the gap disappeared.

|

| sigh |

I dry clamped the top 3 times before I glued it up. All three dry attempts I had problems flushing these edges. However, I didn't have any hiccups get it flush when I tightened the clamps. That changed when the glue went on. It was flush initially and when I finally got all the clamps tightened down, I saw this. By the time I saw it and tried to fix it the glue had already set. This is the major reason I went with 5/4 cherry for the top.

|

| glued and cooking |

I used the Bessey clamps to keep the joint lines flush and tight to the clamps. Got a surprise when I checked the joint line from above again. It had closed up a little more. I should be able scrap away what it is now there with the Stanley #80.

Real crappy day here in RI. The weather seers said it would rain, sleet, and snow off and on all day long. Some rain, no sleet as of this blog typing but it did snow for about 20 minutes. The seers said that none of the precipitations would accumulate.

accidental woodworker

End to side-edge joinery, part 8

Six Spoons

new miniature chest pt IV......

I haven't forgotten about Miles desk. I have decided to make a copy of the desk that I use. Mine is red oak and Miles will be cherry. For that matter, Leo's desk will be cherry too. I wanted to finish the current plate of projects before jumping into the desk build. Now that the miniature chest woodworking is done, the first thing on the desk agenda is making the top. I have the measurements of my desk but I won't be following them exactly. They will be subject to whim and what I think looks good.

|

| hmm.... |

I applied wood putty to the dings and divots on the chest yesterday. The

chest will be rustic looking but I don't want to see all the boo boos

under the milk paint to come.

|

| hinge mortises done |

I had three sets of these hinges, two in bronze and one brass one. The brass one was buried in the hinge goodie bin. Got the heebie jeebies thinking I was losing it again but I found it.

|

| chamfer done |

I stopped the chamfer 1 1/2" from the back edge of the lid. I did this with my battery operated router.

|

| looks a wee bit rough |

This is making my OCD tingle a wee bit but I'll try to get over it. The mortise is shallow leaving the hinge is 1-2 frog hairs proud.

|

| prepping for milk paint |

The last milk paint I used the last miniature chest didn't cover/stick to the wood putty well. So I applied shellac to them and the end grain of the front and back. Not sure how milk paint will do on end grain but the shellac sealed it and it should act as a primer coat.

|

| done, for now |

Decided on how the back doohickey thing will be attached. The lid will be painted red and the doohickey will be finished with shellac. I attached it with 5 screws and I will remove it before I paint/shellac it. Once the finish is done, I'll screw it back on.

|

| finger grabbie thing |

The lid overhangs the front of the chest only about a 1/4". Decided that wasn't enough to ease opening the lid so I added this to help out.

|

| ready for paint |

Spent about 30 minutes with my head buried in my arse searching the shop for some window sash metal chain. I know I had some left over but as usual I can't remember where I hid it. I'll search/order some from Amazon. I have time before I'll need it.

|

| sigh |

Well, boys and girls, they ain't done yet. The cherry one was borderline but the two walnut ones needed some help with the top edges on the ends. After dinner I'll eyeball them again and more than likely they will get another thin coat of shellac.

I had to go the VA after lunch because one of my meds ran out. The doc will review it and I'll get the refill in the mail. In the interim I got a ten day supply. The streets leading to the VA were a complete mess. I thought the side streets were I live were bad but the ones in Providence were way worse. A 5 minute ride through them pre blizzard took me 20 minutes today. Thankful that I don't have to go to the VA for an appointment until next month.

accidental woodworker

Nava Electric Mandolin Part 5: Completed!

The electric mandolin (e-mando) is now complete! In this video, I give a “guided tour” of the instrument and a demonstration of how the pick-up system works.

And a few photos below.........

Cheers Gary

End to side-edge joinery, part 7

Democratising Handwork in Wood

The isolation of my early handwork prepared me for the hard slog going against the ever-advancing tide of machining wood that almost rendered craftwork dead. You might not know this fact as the reality of the day, but handwork in professional realms was actually gone and in amateur realms it was hanging on by a shaving. In magazines and colleges, the demise took a mere decade to disappear, but they kept a token nod to the past by offering a 5%. Today, that's no longer demise, but real future for the real woodworking we almost lost. My work reestablishing hand methods enabled me to meet the unknown need of future. We paved the way for others, and though it certainly wasn't without great cost in time, financial expense, and so on Other costs were incurred; I spent months travelling away even to other continents, leaving my home and family. Today, we have recharged the world of woodworking with hand methods that defy the world of plugged in only woodworking. Did you know that we own Unpluggedshop.com? Worth mentioning, I think. It's enabled hundreds of other bloggers to put their name out there.

Finding the right bench height for you had been lost to stupidity because so-called experts gave the wrong information to establish it. They said you needed to "bear down on the work from above and overhead" to get the plane to work. You didn't! I gave all the answers and tested my theories through 6,500 students in hands-on classes––my theory has now worked for hundreds of thousands of woodworkers to date.

Finding the right bench height for you had been lost to stupidity because so-called experts gave the wrong information to establish it. They said you needed to "bear down on the work from above and overhead" to get the plane to work. You didn't! I gave all the answers and tested my theories through 6,500 students in hands-on classes––my theory has now worked for hundreds of thousands of woodworkers to date.I have to say something here, though. There is this strange belief in the saying that "you get what you pay for." and i question how many are just paying through the nose far too highly, hence my last blog post speaking about the Democratising Workbench Logic post. What we want and what we need are often two very different things. I want a workbench to work and to actually work well as soon as possible because I want to hold, support and work my wood solidly using hand tools and hand tool methods and not only as an assembly point for machined wood parts. If I don't have one, I just make one, and I go the most efficient route to making certain I can make and make quickly. A workbench with a good vise is both the third hand and the anchor to which my worklife is so far irrevocably hinged. My workbenches, I have made about fifty of them for students in my hands-on classes through the years, have stood firm in the face of fancy and overkill status pieces depicting something intended to be more symbolic or to give some kind of validation to the woodworker. I have used a couple of these fancier workbenches and have found them somewhat lacking because of their clunkiness. None of them were a match for my basic bench. Believe me, twenty studs gets you there and a couple of good days sweat-equity means you will be in a machine-free woodworking saddle.

This picture is dynamic i9n terms of the whole body being engaged with visible muscle and sinew synchronised in action that exposes the power of real and active woodworking. What's the difference between this and most woodworking pictures? It's not posed, whereas the other pictures will be halted and waited on by necessity.

This picture is dynamic i9n terms of the whole body being engaged with visible muscle and sinew synchronised in action that exposes the power of real and active woodworking. What's the difference between this and most woodworking pictures? It's not posed, whereas the other pictures will be halted and waited on by necessity. Other things strike me as democratising too. My theory of working with ten hand tools and three woodworking joints to make almost anything from wood is a truism. In the last ten years, I have built well over a hundred full furniture pieces without machining beyond a bandsaw for resizing. My long-term plan is to never touch a power router again. It's foolish to call it a power tool anyway you look at it. 98% of users use it to mould their stock with classic moulds and rounded corners. The rest of their time is making jigs and more jigs. By using bench planes, I eliminate 85% of all sanding because to sand would be to sand rough and not sand smooth. That's a new way of looking at things, isn't it?

My benches do not have any holes in them and I do not use dogs. The bench stop, that's the metal rectangle in the bottom left of the picture, is one I installed and never used. In practical terms, the clamp in the vise deals with any and all securement if it does not work in the vise. Totally practical and efficient. Again, real woodworking by a woodworker constantly in the saddle.

My benches do not have any holes in them and I do not use dogs. The bench stop, that's the metal rectangle in the bottom left of the picture, is one I installed and never used. In practical terms, the clamp in the vise deals with any and all securement if it does not work in the vise. Totally practical and efficient. Again, real woodworking by a woodworker constantly in the saddle.Hard to imagine the flack I got stating that Aldi chisels back in 2010 were as good as it gets, but I did, and that's because I took the risk. Sixteen years on, I have yet to find and use a chisel that exceeded the quality of my then four-piece set. In fact, they were so good, I bought another set to resize for the in-between sizes I felt were missing like 3/16", 5/16" and 5/8". Of course, being at that time in the EU, the chisels were all metric so 6mm, 10mm, 12mm, 19mm and 25mm. Would I ever pay £100 for a single piece of any kind of chisel? Most likely not. A fancier and more expensive chisel will not make you anya better woodworker. Restoring or reshaping and reworking a chisel probably will, though. The self disci-line of doing such things is never a waste of your time, and you learn so much doing things like that. When I paid £10 for four chisels that I still use every day, I see no reason to spend over £400 for a set that does no more. And then there is this The chisels I bought from Aldi are made with highly substantive tangs that will never turn loose, bolsters that totally and firmly absorb and support every type of work, and they have indestructible hornbeam handles no other wood can beat. I cannot understand anyone using beech or ash, bubinga and so on.

It can be a difficult for any new woodworker reading material saying you need this or that chisel for this or that task. In my 61 years of woodworking, I have only ever relied on a basic bevel-edged chisel. Mortise chisels were made for deep mortises in the days when a man would stand at a bench and make mortises for doors all day long. Who does that any more? When you have half a dozen deep mortises to cut, a basic bevel edged chisel works just fine.

It can be a difficult for any new woodworker reading material saying you need this or that chisel for this or that task. In my 61 years of woodworking, I have only ever relied on a basic bevel-edged chisel. Mortise chisels were made for deep mortises in the days when a man would stand at a bench and make mortises for doors all day long. Who does that any more? When you have half a dozen deep mortises to cut, a basic bevel edged chisel works just fine.So why speak of what you can no longer buy? Well, they did stock them for several years. But I have also run MHG chisels that are made in Germany. These chisels have also proven to be excellent value for money and whereas they offer some of their chisels with hornbeam handles, they also offer more finely polished versions with ash handles. In my view, hornbeam beats ash hands down. Several years ago, I bought their six-piece chisel set because they had everything I wanted in a chisel. I have also used all of these in the everyday of my life and cannot fault them. What is great is that they also offer 2mm and 4mm sizes. These are lifetime chisels, they take a keen edge and hold their edges too. A boxed set of six pieces, sizes 6, 10, 12, 16, 20, and 26mm costs £99, and you can add in the 2mm and 4mm along with other sizes if you want to. These cost only £10 or so and are very hand chisels for several tasks.

I have been accumulating a variety of chisels throughout my lifetime of woodworking. Which of these do I use now. None of the ones pictured. I rely on a simple set of half a dozen bevel edged chisels. I can recommend MHG's set for their excellent quality, taking a keen edge and edge retention. I have tested them for ten years and they have never failed me. For around £100 you will get a good set (six in a box) of lifetime chisels with hornbeam handles.

I have been accumulating a variety of chisels throughout my lifetime of woodworking. Which of these do I use now. None of the ones pictured. I rely on a simple set of half a dozen bevel edged chisels. I can recommend MHG's set for their excellent quality, taking a keen edge and edge retention. I have tested them for ten years and they have never failed me. For around £100 you will get a good set (six in a box) of lifetime chisels with hornbeam handles.Deep or shallow, hardwood or softwood, my chosen chisels have yet to fail me. My nudge back in the day meant Aldi sold out in every one of their stores here in the UK. Unfortunately, they had to stop stocking them. So why do I say what I say? Well, the sellers of hand tools go to much trouble reasoning out why you need a set of chisels for this kind of work and then another type for that. 98% of them you just do not need, no matter the work, the shape or the size of it. The men I worked under as a boy apprentice through to a journeyman, two different companies, seven years in all, had a half dozen bevel edged chisels on the benchtop, never pulled out a massive mortise chisel for the deeper pockets, never used square edged firmer or registered-pattern chisels, and they got along day in and day out throughout those years just fine no matter the task nor the wood. These men democratised in their day in the same way I do now. The cost of my working chisels over a hundred years come to 00.oo2083333333r of a penny or cent a day.

This is my democratised, nuts and bolts workbench that surpasses the expectation of any woodworker and furniture maker. You can see it being built in my back garden when I lived in the UK's North Wales. I add various components to customise it for functionality. But for £70 you can be working at it in just a few days, no more than three, I'd say

This is my democratised, nuts and bolts workbench that surpasses the expectation of any woodworker and furniture maker. You can see it being built in my back garden when I lived in the UK's North Wales. I add various components to customise it for functionality. But for £70 you can be working at it in just a few days, no more than three, I'd sayI started selling my excess of hand tools to put the now unused back in circulation. These were the ones I used in my hands-on classes, and then those you just can't pass up. I posted a very nice Stanley #4 1/2 on eBay for £25 and had no takers. I was surprised but hey ho. I did at one time go to the wider #4 1/2 and #5 1/2 planes. I realised that people were copying what I did, and that for 90% of those new to woodworking, these were too bulky and prohibitively heavy for them. Even before that, though, I found myself reaching for my #4 Stanley almost every time. That small width difference of a mere 5/16" makes a big difference in both weight and sharpening to a man working full-time and making 98% by hand only. I'm a machineless woodworker, aside from a single bandsaw. A #4 weighs in at 3.68 lbs pounds and a #4 1/2 at 4.8; that makes the latter about the same as a Lie Nielsen #4 BedRock, that's not so small an increase, and it would make a huge difference, and especially to those not used to upper-body work for long periods.

An MHG 1" chisel honed to perfection removes the arris as a leading edge for the tenon into the mortise hole. Keep it real, keep it simple and keep it low cost using a tool made for working people to get the action they truly need.

An MHG 1" chisel honed to perfection removes the arris as a leading edge for the tenon into the mortise hole. Keep it real, keep it simple and keep it low cost using a tool made for working people to get the action they truly need.You do not need weight, but you do need sharp!

The Stanley #4 is a light in weight in some measure, but it's no lightweight in performance in any way. The fact is this: this plane, not the BedRock version but the Leonard Bailey common-or-garden one, is not just iconic but the most perfectly designed of all all-metal versions through the last century and a half bar none, and that's for a wide range of tasks. Beefier bulldogs might like to persuade you otherwise but that's the difference between riding an Arabian stallion where you can twist, turn and flip to task in a heartbeat as opposed to plodding along on a heavy draft like a Belgian draft or a Clydesdale. A kayak can flip, roll, twist, twitch and switch on a sixpence or a nickel, but an oil tanker might take a good half day or more to even stop, let alone turn end for end. So even within the same overall size, the copycat BedRockists of our new era, new generation bench planes made by plane makers now makes even a #4 size heavy-metal plane prohibitive and of little if any intrinsic value. So I weighed three modern-day versions made by so-called premium makers and compared them to my now 61-year-old Stanley, the current one I have been using every single day over my ten-hour day days, and the weight difference between an average of these and my basic, non-retrofitted #4 Stanley makes them quite, well, sluggish. You see, metal soles on wood do stick more than their wooden counterparts, enough to feel about ten times heavier. The heavyweights make that feel like twenty times heavier, I can tell you, and that is what makes them less versatile.

Currently, working my two planes side by side through the decades, and despite the fact that I don't grind the bevels using any grinding machine, two plane iron lasts me for about 6 years. Here I show the point at which you must abandon one.

Currently, working my two planes side by side through the decades, and despite the fact that I don't grind the bevels using any grinding machine, two plane iron lasts me for about 6 years. Here I show the point at which you must abandon one. Another issue that is never mentioned, so I will do it here because makers never do and owners don't even know it: The advantage makers and users extol is that you can adjust the mouth opening without removing the cutting iron assembly as they say you must do with a Bailey-pattern frog in the common Stanley's, but you actually don't. . .read my book Essential Woodworking Hand Tools. 1. You rarely if ever need to adjust the throat opening on a bench plane. I never alter this setting, and that's because with a sharp and well set plane you DO NOT NEED TO. 2. If you do that on a Bailey pattern, you do not alter the cutting depth. Now on a BedRock pattern plane, when you are advantaged by not having to remove the cutting iron assembly, you are then majorly disadvantaged because the depth of cut is changed, and you have no idea by how much. So, for around £20 you can buy a secondhand Stanley #4, spend an hour fettling it and bringing it out of hibernation because it went dull, and you have a lifetime plane. And think about this; if I have used my #4 every single day for 61 years, gone through six cutting irons yet I don't grind them of grinding wheels, how long would it last you using it for a couple of hours a week?

In functionality, there is no difference between the three heavier planes and there is no maker offers a new and innovative invention on any of them to improve innovatively. That says a lot and speaks very positively of Leonard Bailey, who developed the whole of the bench plane bodies for Stanley stable back in the late 1860s, doesn't it. In 150 years since Leonard Bailey had the concept, no one has changed a thing. Imagine!

In functionality, there is no difference between the three heavier planes and there is no maker offers a new and innovative invention on any of them to improve innovatively. That says a lot and speaks very positively of Leonard Bailey, who developed the whole of the bench plane bodies for Stanley stable back in the late 1860s, doesn't it. In 150 years since Leonard Bailey had the concept, no one has changed a thing. Imagine!The three heavyweight BedRock #4's averaged 4.7lbs, whereas the Stanley comes in at 3.6lbs. That's what I call refinement with the user in mind. Nothing prissy about a plane that works for a man like me for six decades of daily making with hand tools, I'd say. These makers could learn a thing or two about listening to their customers rather than telling them what they need. It mightn't seem much but believe me, those heavyweights would translate into many a dozen tons over a 61 year daily-use span of someone like me.

My initial concern is prohibition. As a new woodworker starting out would I want to spend £400 on one tool that only planes wood after I have learned to sharpen and set the tool up. For a new woodworker starting out, it is but a temporary benefit to buy a plane that might be ready to go out of the box. Within an hour, they must resharpen and set the tool, and therein lies the issue. Why not just put your boots on and get in the saddle straight off at one twentieth of the cost. A Stanley number 4 will cost no more than £20.

So there it is, my faithful friend. We shake hands with poise and class every day and all day whenever we meet and get to work. We work as a perfectly balanced team, you see. How clever is that! We've settled many a twisted stick stem and board together.

So there it is, my faithful friend. We shake hands with poise and class every day and all day whenever we meet and get to work. We work as a perfectly balanced team, you see. How clever is that! We've settled many a twisted stick stem and board together.And then I see some of the dumb things elsewhere too. Imagine anyone, people woodworking, spending upwards of £150 for what is no more than what we once called a "toffee hammer", 4 ounces of metal that is. The supportive comments matched the weight of the hammers I looked at. My best shot is the pretension of it all. One author started out saying, "You really don't need one of these..." and the pretension all went downhill from there. I use a couple of cross-pein hammers in my day to day, A 12 ounce Warrington version by Stanley gets me there on all types of plane iron adjustment, including tightening wedges and shocking them loose in wooden or metal planes. My 12 ounce drives panel pins and metal parts. And then there is my 6 ounce "toffee hammer" made by Stanley here in Sheffield.

Wood on wood works remarkably well, and you would be stunned if someone gave a wooden plane, freshly sharpened, to true up even a wide board of oak, maple or walnut. It took Stanley Rule and Level 50 years to persuade the ancients to switch to metal-soled planes, and that wasn't because they refused progress, but because the metal planes stuck like glue to the wood by comparison with the wooden planes they were used.

Wood on wood works remarkably well, and you would be stunned if someone gave a wooden plane, freshly sharpened, to true up even a wide board of oak, maple or walnut. It took Stanley Rule and Level 50 years to persuade the ancients to switch to metal-soled planes, and that wasn't because they refused progress, but because the metal planes stuck like glue to the wood by comparison with the wooden planes they were used.These hammers are clearly winners for me. Nothing wrong with using a steel hammer to set your plane irons with or adjusting wooden plane iron depths on moulding planes either. The wide face of the hammer head has nothing prissy about it, and the cross pein fits in to the tight corners right where you need it. Oh, and did you know that the cross pein enables you to drive 1/2" pins between your forefinger and thumb no problem?

Here you have the reality of a tool in use. The cross pein is perfect for starting tiny pins between the thumb and forefinger and then seating it with the bell side.

Here you have the reality of a tool in use. The cross pein is perfect for starting tiny pins between the thumb and forefinger and then seating it with the bell side.The cross-pein Warrington in different sizes is available as a vintage version secondhand on eBay. This remarkable cast steel hammer is a lifetime tool, and I have three sizes that I have used throughout my daily work life.

My 6 ounce Warrington still drives pins but also helps to set and align plane irons in wood-bodied or cast metal planes. I perfect synchrony without any compromise. But then a heavier version does the same. I have three weights of Warrington hammers 6, 10 and 12 ounce.

My 6 ounce Warrington still drives pins but also helps to set and align plane irons in wood-bodied or cast metal planes. I perfect synchrony without any compromise. But then a heavier version does the same. I have three weights of Warrington hammers 6, 10 and 12 ounce.For adjusting all of my planes, moulding planes, cast metal and wood versions and so on, I use this 6 ounce Stanley Warrington hammer. I bought this one new in 1965.

new miniature chest pt III......

|

| now they are done |

No home for either one of these. I'll ask my sister Donna if she wants them. If not I'll give them to my sister Kam. I still have to get a hold of her for day to bring the boneyard goodies to her.

|

| 3 more done |

The middle cherry one is for Miles desk. The two walnut ones are homeless for now. But I am thinking of gifting one of the walnut ones to Maria at the Frame it shop.

|

| hmm.... |

Got the moldings in and the two long ones are a few frog hairs higher then the short ones. I had checked them and it looked to me that they were all the same height. I'm leaving it as is. I just nailed the moldings in place with no glue. I didn't glue the plywood bottom to the bearers neither.

I hand nailed one short molding and pin nailed the others. There was barely any room for the hammer head to hit the nail. Nailing it off with the pin nailer wasn't much better but I managed to get it done.

|

| hmm...... |

Thinking about how to attach the back doohickey thing. Clamp and nail it, or use screws? Also, do I do it before the hinges are attached or do it after? Good place to kill the lights and head topside. This was all I got done today in the shop. Spent the rest of the day watching old Star Trek shows on Amazon Prime. I never saw the first few years of any of them.

accidental woodworker

new miniature chest pt II......

|

| hmm......... |

These two were the original ends] for the miniature chest. The bottom one is dead flat and is the one I had clamped a split/crack in. The top one was flat but it ain't anymore. No problem flattening it with hand pressure. No idea what I'll use these for but they will be available in the scrap pile.

|

| glamour pic |

I like how this turned out. Initially I wasn't happy with how the bandings were applied vice inset in dadoes/grooves. Now that I can eyeball it with the lid on, I like the look.

|

| hmm..... |

I think the feet being applied and proud help to anchor the bandings. There is a lot of color and texture from all the different woods to look at.

|

| oops |

Thought I was done with it but it ain't so boys and girls. I missed getting shellac on the inside of the top of the lid.

|

| nope |

I had left the cupped, smaller doohickey clamped over night and most it was gone this AM when unclamped. However, I ripped out another one a 1/4" taller and a few frog hairs thicker.

|

| got lucky |

The top has 4 coats on it and the pine has a light honey color that compliments the cherry insert nicely.

|

| the after pic |

The lid had cupped slightly and no matter which way I put it on the top there was a gap at the front. Put the board on the bench and planed the hump flat first and then the cupped side second. I only lost a 16th on the thickness too - ended up at 11/16".

|

| sigh |

Today the chest was rocking. Put the sticks on the legs expecting to see some twist and nada. The sticks told a tale of zero twist so why was it rocking?

|

| the problem?? |

The miniature chest is on the tablesaw laying dead flat and zero rocking. On the blue outfeed table it was rocking. No rocking on the workbench neither. Looking back I think this table was causing the headaches I had with the walnut bookshelf. I had checked for rocking first on this outfeed table.

A quick check with a long straight edge showed this table has some twist/hump. I'll stop using this to check for rocking starting today.

|

| molding choices |

I wanted to use the quarter round molding but it is too small. It would be a ROYAL PITA trying to nail or glue it in place. I am going to use the beaded molding on the right. This one I can press down tight to the plywood bottom and nail without any hindrances that I can foresee.

|

| 3 coats of shellac |

Almost done. It looks ok with three but one or two more will raise the shine up a couple more notches.

|

| one more coat to come |

I had to scrape waterfall drips on all three of the bookshelves. One more light coat of shellac and they will all get a check mark in the done column.

accidental woodworker

The Japanese Gennou Hammer & Handle Part 20 – Making Sawdust

Woodworking minus patience equals firewood.

– Author Unknown

In the previous article in this series, we selected and prepared the wood for our gennou handle and layed-it out in accordance with our design drawings.

The next step in the process is to gather our tools and begin the fun work of making sawdust. Yeeehaaaa!

Tools

I prefer to use the following tools when making a gennou handle. You will need to have similar tools on hand for layout and fabrication, but the specific choice is entirely yours.

- Divider with sharp points (transferring dimensions and tenon layout);

- Sharp pencil (making pencil marks (ツ);

- Small try square (laying out and checking tenon);

- Marking gauges (Titemark and kama kebiki. Marking tenon and centerlines) ;

- Marking knife (layout);

- Rip handsaw for roughing out;

- Hozohiki rip saw and/or dozuki crosscut saw and/or rip saw for cutting the tenon (in hardwood, a sharp hozohiki rip saw frequently makes both rip cuts and crosscuts cleaner and more precisely than a crosscut dozuki saw);

- A fine saw such as a fret saw or coping saw with a fine blade for making curved cuts;

- Auriou cabinet rasp (Lie-Nielson) (optional);

- Bogg-pattern flat-sole spokeshave (Lie-Nielson) (optional but really handy);

- Sandpaper;

- Satin Polyurethane finish (optional);

- Mineral spirits (optional.

- A board to support the handle-in-progess. I suggest dimensions of 300-400mm long x 50-60mm wide x 40-50mm thick, with a “V” groove cut full-length and a cross-stop inlet about 2/3 its length. The handle will rest, more-or-less securely in this groove, and be restrained at one end by the stop when using spokeshaves and rasps. This support board can be clamped in a vise, or clamped to a workbench with a C clamp. I also find it most efficient to place this board on my benchtop with the gennou handle resting in the v-groove with one end touching my chest, perhaps cushioned by a rag, and use rasps and spokeshaves pulled towards me to shape the wood.

The Tenon and the Unblinking Eye

Let’s start by cutting the tenon and fitting it to the gennou head’s eye.

You’ve already layed-out the tenon, so use a fine precision rip saw like or 210mm hozohiki to cut the four cheeks being extremely careful, like a big-eyed kitten stalking a grasshopper, to stop short of the layout line. Be careful to work very precisely with your saw to not cut too deeply as any excess meat removed from the tenon, or sawcuts left in the tenon, will fatally weaken it. I’m not kidding!

I’ve made this mistake more than once, ruining all my work to that point and wasting some nice wood. Indeed, it may be best to cut the shoulders shallow and trim with a chisel, once again being careful to not cut too deeply. Ruthless, merciless, unrelenting control of your naughty inner-badger is critical!

At this point, the handle is a chunky, graceless block with square edges and flat surfaces. That’s alright. There’s no need to contour the handle yet.

Cut itsy-bitsy teeny-weeny chamfers on the end of the tenon to help guide it into the eye without cocking and binding. A big chamfer will benefit nothing and look ghastly.

Mark the reference face annotation on the corresponding tenon cheek because you don’t want to mistakenly force the tenon in bassackwards.

Test fit the tenon into the eye a few millimeters but without driving it all the way on. It should not start by hand pressure.

Although you shouldn’t have to try tried a full-power test fit, when you are satisfied that the tenon will fit into the eye of your gennou head without the driving forces shaving off much wood, and marked the reference faces, then tape the tenon with masking tape so you don’t accidentally knick or shave it. Don’t ask me why I know this risk exists.

With the tenon close to completion, let’s next shape the curved front, back and side surfaces to fit.

The Back and Front Edges

Cut the back and front edges (surfaces parallel with the long axis of your gennou head) to your design profile using saws, rasps and/or spokeshaves. The two guiding details in this process are the butt and the tenon, with the tenon being most important. These two surfaces should be shaped to smoothly connect the butt with the tenon, not the other way around.

However, leave the corners square for now to help guide you in shaping the critical back and side surfaces because, if you start rounding and smoothing edges and corners now, it often happens that the geometry which aligns the hammer’s face with chisel and nail will be compromised.

The tools you use don’t matter so long as when this step is complete the back edge is perpendicular to the reference face, the opposing side face, and is consistent with the layout lines.

I recommend you cut outside the layout lines plus a millimeter or two because accidentally cutting deeper than your layout lines will not only disrupt the even flow of the design but may damage the structural integrity of this elegant, minimalist tool.

Do not cut or shave the handle’s sides flush with the tenon yet, but leave them just a hair proud.

When done with the this, lightly remark the centerline and extended the eye’s lines.

The Sides

At this point in the process the right and left sides should still be flat and parallel, perpendicular at any point with the back surface, and have neat, square corners.

Use the paper/cardboard profile pattern from your design drawing to mark the handle’s layout on the back and front edges.

Just as with the back and front edges, cut the side surfaces using saws, a drawknife, rasps and/or spokeshaves.

The transition from tenon to butt should be uniform and smooth. As you approach the final dimensions, be careful to avoid tearout or gouging in the neck area since removing these irregularities may require you to reduce thickness too much.

Do not cut or shave the sides flush with the tenon’s cheeks yet, but leave them just a hair proud.

Smoothing and Rounding

I find it most effective to leave the back edge (opposite the flat striking surface of the head) flat with slighty relieved corners. Some people like to make the back edge of the handle oval or egg-shaped, but I recommend you leave it flat at first and then adjust it to fit your hand as you use the gennou.

Common sense will scream at you in a voice like a nazgul to round the the back surface or to make it oval-shaped, but while such surfaces might look better hanging on a peg in a hardware store, or feel better when using your hammer to kill coackroaches, it is counterproductive when doing serious work, I promise you.

Why? Because, despite what you may think, a flatter back surface does not bite into the hand in-use, but because of the greater surface area in contact with the hand it provides, actually reduces the pressure of impact reaction forces on the hand reducing fatigue and bruising. More importantly, it helps with quickly and unconsciously indexing the striking face of the head correctly.

With the back edge where it needs to be, next round the front edge into the design profile. I prefer this surface to be more-or-less a perfect radius at any point in the handle area, but some guys feel an egg-shaped cross-section fits their fingers better. Six of one half-dozen of the other.

In any case, this surface must smoothly morph into a flat surface with slightly radiused corners in the neck area, and finally with no radius as it approaches the tenon. Yes, you read correctly: no radius.

I usually round-over the flat on the back edge right where my index finger wraps around to the side just a little to avoid developing a blister. But keep in mind that the only way to tell what small details works best for you is trial and error.

Doming the Butt

The butt should be flat with sharp edges at this point in the process.

You may find a domed butt strange, but it has both a practical purpose and an aesthetical one.

Let’s consider the structural, practical purpose first. If the wood is adequately hard, and the tenon is not too skinny, you will need to hammer the butt like a son-of-a-gun dozens of times to get the tenon into the eye. Don’t start yet, but when the time comes you must be careful with the direction of your hammer strikes to avoid breaking the tenon.

If the butt is flat with crisp edges, unless you have perfect aim with every swing, your hammer might chip or even split the butt. A domed surface directs impact forces away from the edges of the butt and into the neck, helping to prevent chipping. Likewise, a curved butt will also reduce damage to the handle over many years of hard service.

With regards to aesthetics, a domed surface is more organic and, to my sensibilities, more elegant than a flat one because straight lines seldom exist in nature, are boring to the eye, and seldom please it.

A warning. Everyone has different opinions about what pleases the eye, as you know. Beauty is in the eye of the bean holder, or something like that, so I entirely understand if you dismiss the aesthetic reasons I’ve suggested. But please don’t ignore the practical, structural reasons if you want to avoid wasting your time and wood.

Assuming the butt is flat and its surface is more or less perpendicular to handle’s centerline, use a marking gauge set at ¼” to scribe a shallow line along the handle’s edges and sides. Lightly scratch another shallow line the same distance around the perimeter of the butt. These lines will be the limit of the chamfer between the grip and the butt.

Next, mark a cross on the butt using the front and back edge’s centerline, and a perpendicular line parallel to the back edge. This cross will be useful in profiling the butt.

Use a knife, chamfer plane, block plane, files or other tools to chamfer to the lines just scratched.

Next facet the butt using planes or a sharp kiridashi kogatana knife and remove all tearout and filemarks. The time for using sandpaper will come later in this adventure when we apply finish.

Fixing a Loose Head

So here’s the “I toljaso” in advance.

If you were not a clever little big-eyed kitten when fitting the tenon, you may find the tenon becomes loose and the head begins to wiggle with the passing of a few seasons. A Sergent Elias moment!

I won’t say it out loud, but just between you and me and CCP you can remedy a loose head by removing it and shimming the eye with quality high-rag-content typing paper. Don’t have any such paper in your bat cave? Don’t tell the Secret Service I said so, but a strip cut from a dollar bill works best. Crane Stationary makes the best paper in the world.

In the next post in this series we will attach the gennou head to the handle.

Until then, I have the honor to remain,

YMHOS

Lena Dances With the Knight by John Bauer 1915

Lena Dances With the Knight by John Bauer 1915

If you have questions or would like to learn more about our tools, please use the questions form located immediately below. To see a list of our tools and their pricing, or to contact us, please click the “Pricelist” link here or at the top of this page.

Please share your insights and comments with all Gentle Readers in the form located further below labeled “Leave a Reply.”

We see data miners and their bots as dastardly sneak thieves and so promise to never share, sell or profitably “misplace” your information for any reason. If I lie may the heads of all my eyes become egg-shaped!

Previous Articles in The Japanese Gennou & Handle Series

- Part 1 – Introduction

- Part 2 – Ergonomics

- Part 3 – What is a Gennou?

- Part 4 – The Varieties of Gennou: Kataguchi, Ryoguchi & Daruma

- Part 5 – Kigoroshi

- Part 6 – The Ergonomic Anaya

- Part 7 – The Unblinking Eye

- Part 8 – Head Style & Weight

- Part 9 – Factory vs. Hand-forged Gennou Heads

- Part 10 – Laminated Gennou Heads

- Part 11 – Decorative Gennou Heads

- Part 12 – The Drawing: Part 1/6

- Part 13 – The Drawing: Part 2/6

- Part 14 – The Drawing: Part 3/6

- Part 15 – The Drawing: Part 4/6

- Part 16 – The Drawing: Part 5/6

- Part 17 – The Drawing: Part 6/6

- Part 18 – Wood Selection

- Part 19 – Laying-out the Handle

new miniature chest......

|

| cooked overnight |

This was going to be the ends for the new miniature chest. Didn't know it here yet.

|

| eats up a lot of real estate |

The bottoms are done on all of them. Next up is getting 4-5 coats on the rest of them.

|

| yikes |

One of the ends and this decided to shake hands with me. There was a split/crack on one end what when I tried to open it up so I glue it, it split opened from end to end. It didn't separate entirely making it easier to fill it with glue and clamp.

I made another end but it was thicker than the other original one. I had the stock so I just made another end panel so the two would be the same thickness.

|

| one miniature chest |

There is surprisingly little stock required to make this chest. Two ends at the front with the front, back, and lid behind them.

|

| came yesterday |

This a 1/2" timber wolf wood slicer resawing bandsaw blade. I got it from Highland Hardware. Can't wait to see if this is the cats meow for resawing.

|

| hmm..... |

The fence and the blade ain't square to the table. Fixed that boo boo before I tried resawing again.

|

| big negative on that Houston |

The 3/8" chinese bandsaw blade had zero problems ripping through this pine. Unfortunately for me the cut was far from stellar. Parallel at this end (the entry) but angled on the exit.

|

| this ain't good |

Again, the blade eased through this better than a hot knife going through a tub of cheap oleo. This cut is something new for me. I had tried to push the stock through the blade like I have seen on a bazillion You Tube vids. The saw cut had a mind of its own than this was what it wanted to do.

|

| yikes |

This was the last resaw I attempted. I pushed the stock through the blade. I didn't go nutso pushing the stock tight against the fence as I pushed it forward. I have yet to see one You Tuber pushing against the fence as the stock is fed into the blade. Time to step back, resist the urge to give free flying lessons, and think about what the (*^)(_*(!@$^&*)_@(+$ am I doing wrong.

|

| need a dutchman |

The grain is uplifted here and it will be a catch hazard. A dutchman will cure that hiccup.

|

| good fit |

It is ready to glue with a few gaps. My initial knifing of the dutchman was faint and I had trouble refining them when I chiseled the outline.

|

| glued and cooking |

No need to clamp this. The dutchman fit snug.

|

| why????? |

One continuous cut, smooth with zero binding or hesitation. Why can't I duplicate this cut with resawing?

|

| comparison |

Sawed these notches on the bandsaw. Smoothed one and the top one awaits its turn. The amount of scalloping wasn't effected by pushing it slowly or fast through the blade. Rough as it is/was, it was square to the face.

|

| hmm...... |

The side panel is proud of the leg on the end. This is harder to fix then if the leg was proud of the side panel.

|

| fixed |

The side panel and the leg are flush now. I used the same fix on all four legs.

|

| the fix |

Planed four strokes with the LN 140 making a shallow rabbet. I wasn't too concerned about an exact depth. If it was a little too deep, a few strokes with a plane on the leg would flush it. Nailed the front and back on with 5 cut nails on each end with a wee bit of glue.

|

| ledgers |

Nailed and glued the ledgers on that are for the plywood bottom to be secured to.

|

| bottom in dry |

Thinking on whether or not to put a molding here to keep the bottom in place. I did that on the previous miniature chest and I like it.

|

| lid and the back doohickey thing |

I like the proportions of this miniature chest more than the previous one. The length to width ratio looks better to the eye IMO.

|

| hmm...... |

The doohickey thing has a healthy cup to it. I was able to clamp and flush it with the back edge of the lid. Not getting a warm and fuzzy with it in spite of the ease with flushing up. I would rather have doohickey thing be straight and flat from the git go.

I hadn't expected to get this far with the chest today. After I got the front and back nailed to the ends, everything else just fell into place. No hiccups or road blocks. This will be painted with milk paint and the pigment dyes I bought. Blue for the main body and red for the lid. At least that is the plan as of today.

accidental woodworker

a wee bit sore........

The old body isn't screaming at me but it is achy through my back into my upper thighs. What surprised me was my left shoulder didn't hurt. There was a wee bit of achiness but no rip your face off pain.

The plow truck came through overnight and it was expected. They blocked off the end of the driveway and the front door walk way. They also only plowed my side of the road. They made another run around lunch time. So I had to shovel twice more today but I lucked out because it wasn't nowhere near the blizzard level snow dump.

|

| sigh |

Not too bad and it took me a little less then an hour to clear the driveway and the front door walk through. No hiccups with the left shoulder, I was expecting it to start singing arias within a heartbeat but it didn't.

|

| hmm....... |

It is signed 2023 but I would bet a lung that it was older than this. I think I signed this when I hinged it. I know this sat in the boneyard for several years without hinges. This is the pine/cherry jewelry box and I'm slapping shellac on it finally.

|

| sigh |

The banding is offset on this corner. It looked like crap and was setting off alarm bells in OCD central. Chiseled it off and glued on another piece.

|

| wow, and wow again |

I can't believe how dark the legs and bottom banding on the small box popped after just one coat of shellac. I think this is ebony but I'm not sure. Regardless, I am in love with the color.

|

| flattening |

I didn't go nutso on this. I planed the hump on one face and the cup on the other. Made no attempt to make the faces dead nuts parallel. No pain working with 3 different planes flattening this board. I wasn't sure if the left shoulder would protest or not.

|

| done |

Happy face on. The board ended up 11/16" thick which was my target.

|

| resaw time |

The blade is only 3/8" but it didn't protest resawing this scrap of pine. The blade effortlessly glided through the board with no binding or hesitation.

|

| hmm....this sucks pond scum |

In spite of the ease sawing the stock it didn't come out okey dokey. The saw cut is angled. The outside cuts aren't usable but the middle one is.

|

| why I was resawing |

This board will give the ends for the miniature chest. I am going to dutchman this pitch pocket but not the knots. Pitch pockets can bleed and run when the temperature gets hot.

|

| second step |

Knife and the chisel the outline of the dutchman. I chiseled it out and checked the depth with an adjustable square.

|

| good fit |

There is a bit of a gap on the top long edge. It isn't a big deal and

I'll fill it with wood putty. This is going to be painted and won't be

seen.

|

| glued and clamped |

Tomorrow I plan to go to Lowes and buy a couple of 1x12 pine boards for the miniature chest. I'll whack that out before I start on Miles's desk.

|

| two coats of shellac |

Two coats on the body and three coats on the feet. One more to go on them and they I can finish the rest.

accidental woodworker

Update on the Dunlap #3726 Bench Plane

I had been having trouble getting this plane to work properly. The front of the frog does not make contact with the plane's main casting; it is essentially cantilevered over the casting forward of where its seat mates with the casting's frog receiver.

|

| With frog bolted down, can fit cardboard under the toe of the frog |

And this caused the plane to shudder as it tries to glide over a workpiece.

|

| You can see the waviness of the cut |

I thought if I filled the gap under the frog, the cantilever would be eliminated and maybe the plane would be more stable and cut better. First, I stuffed a few layers of business card under there to see what the gap measured. Turned out to be about 0.052". I planed some maple to 0.056" thick - no small feat - and stuck another block to it to fill not only the space under the frog's toe, but also the space under the frog just forward of the casting's frog receiver.

|

| The block and a piece of thin maple |

My intent was that the top of the block would be in line with the top of the frog receiver, the slanted part would match the roughly 45 degree angle on the underside of the frog, and the thin base would support the frog's toe. This turned out to be a major pain in the ass, as I had to fit the piece, bolt on the frog, test it out, take it apart, make minor adjustments and repeat - many times.

In the end I would have needed to whittle away most of the slanted part of the block to allow the frog to be far back enough to bolt it down. So I tried something much simpler - just go with a thin piece of maple, 0.056" thick, under the toe of the frog. In the following picture, you can see the piece of wood in place.

|

| Looking at the sole from toe end - the white is the maple piece |

Well, time will tell if this fix works for the long haul, but for now, the plane seems to be working fine. I planed some pine with no juddering, then some red alder (a relatively soft hardwood) and some pretty hard red oak, all with a nice smooth surface finish.

|

| Planing some fine shavings of red oak |

|

| Nice smooth surface! |

Could it really be as easy as that? Maybe I'll keep this plane after all. But if there is anybody out there who collects Dunlap planes and would like this one (for free), please contact me and I'll be happy to let it go.

Latest Chat With Brian (not woodworking)

A few days, ago my longtime friend retired broadcaster Brian Wilson and I had another of our long-form chats, commenting about the state of the world. He posts these and other musings on his Substack account, Brian Wilson Writes. Feel free to indulge (or punish) yourself as our conversations are definitely no-holds-barred, not for the easily offended.

it wasn't 16 feet.......

I must have gotten some snow blindness because I was way off on how much I had to shovel. 16' didn't even make it to the end of driveway. I measured once I cleared it out to where the plow trucks dumped their stuff. From where I left off yesterday to the snow line in the road was almost 42 feet. I would have gladly accepted it being 16'. I started shoveling it at 0738 and I got done with it at 1248. I worked right through lunch because I just wanted it over and done with.

|

| a little over 3 hours |

I still have a chunk of snow on the right to shovel. My shoulder was starting to hurt a lot here. To add an insult to injury, it snowed for most of the time I shoveled. It turned to rain briefly before ending. On a brighter note, Mr Sun said hello around 1400.

|

| awesome helpers |

These are like football cleats that went on a super crash diet. Absolutely no slipping and sliding with these on. Because they slightly elevate your shoes they don't get soaking wet. I wouldn't have survived shoveling the driveway without them.

|

| almost forgot to snap this pic |

The fruits of my labor. I am going to be sore for a while. I can't lift lift my arm up above my left shoulder. Can't remember whether to ice it or apply heat. I'll google it later on.

I went to Shaws to get some vittles and my street was barely a single lane. There is no way two cars could pass each other. I noticed that a couple of side streets weren't plowed at all. The main road going to Shaws was clear but the left lane (4 lane road) was a wee bit short on the width. That made for an interesting drive dealing with the morons in the right lane.

|

| hmm....... |

This walnut bookshelf didn't want to get its pilot license. It isn't rocking here at all. No rocking when I checked on the tablesaw top neither. I'll be keeping an eye on it to make sure it behaves.

|

| been two days |

I was too impatient to wait another day because I had to see how it looked right now.

|

| about the same |

I really couldn't see any difference after this second heat and clamp. There is still a wee bit of a cup on one face and a hump on the other face. Still much better than what it was before I tried this. When it comes time to plane the hump/cup I shouldn't lose that much in the thickness. Hoping it will be about a 16th or less.

|

| almost done |

This almost didn't get the final check mark today. My shoulder stopped singing arias and was screaming at me. I stayed in the shop long enough to get the last two bandings on and clamped. This was all I got done in the shop today. I don't expect to light the world on fire with shop time in the AM. That is dependent upon how much use my left arm will have to render.

accidental woodworker

Carve an Ice Cream Bowl

The Flywheel, Lathes, and the Industrial Revolution

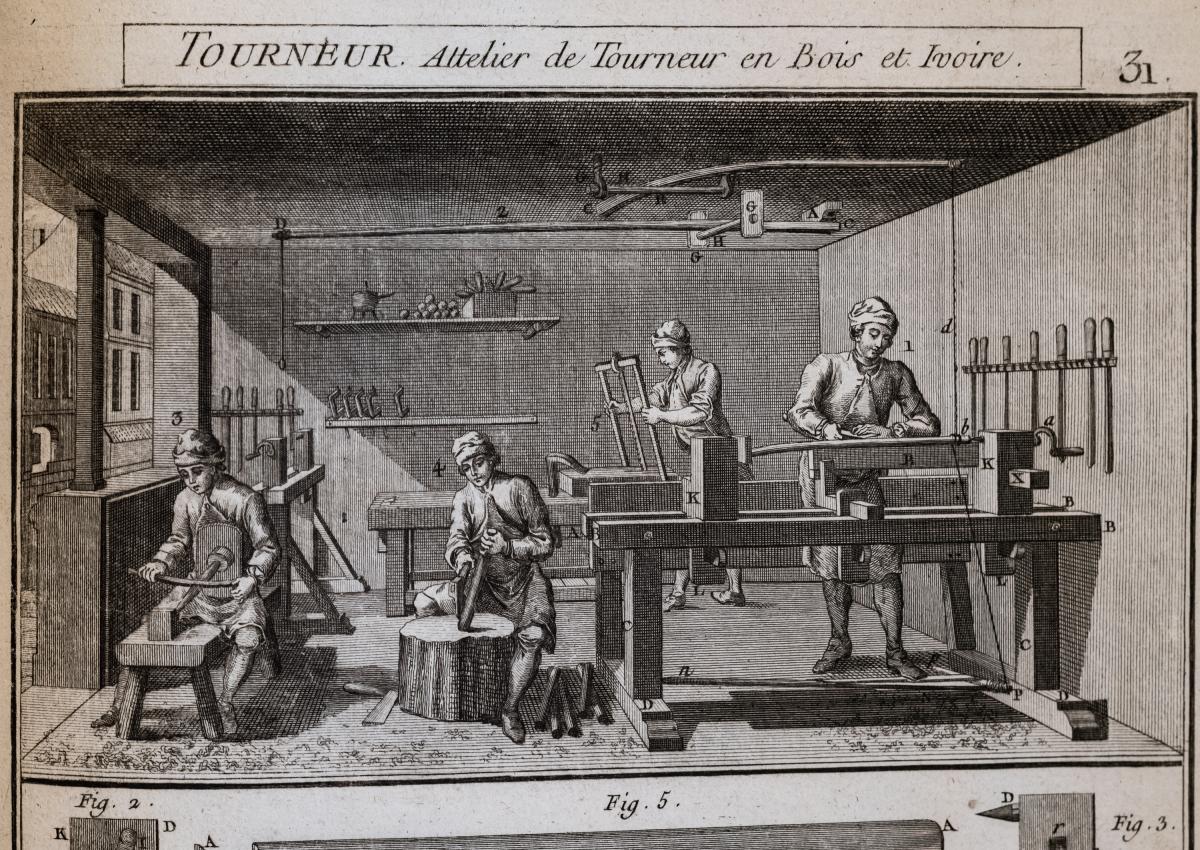

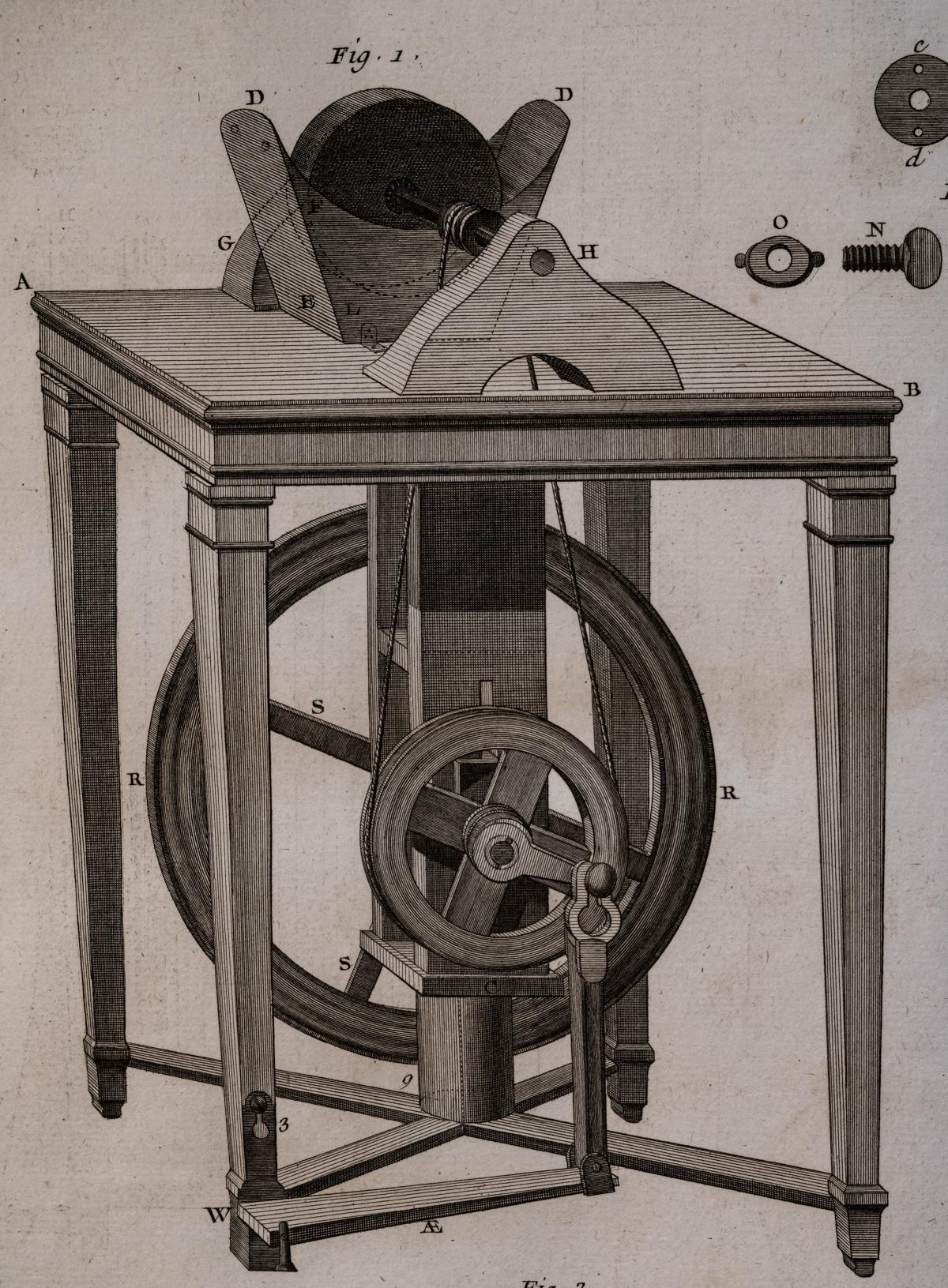

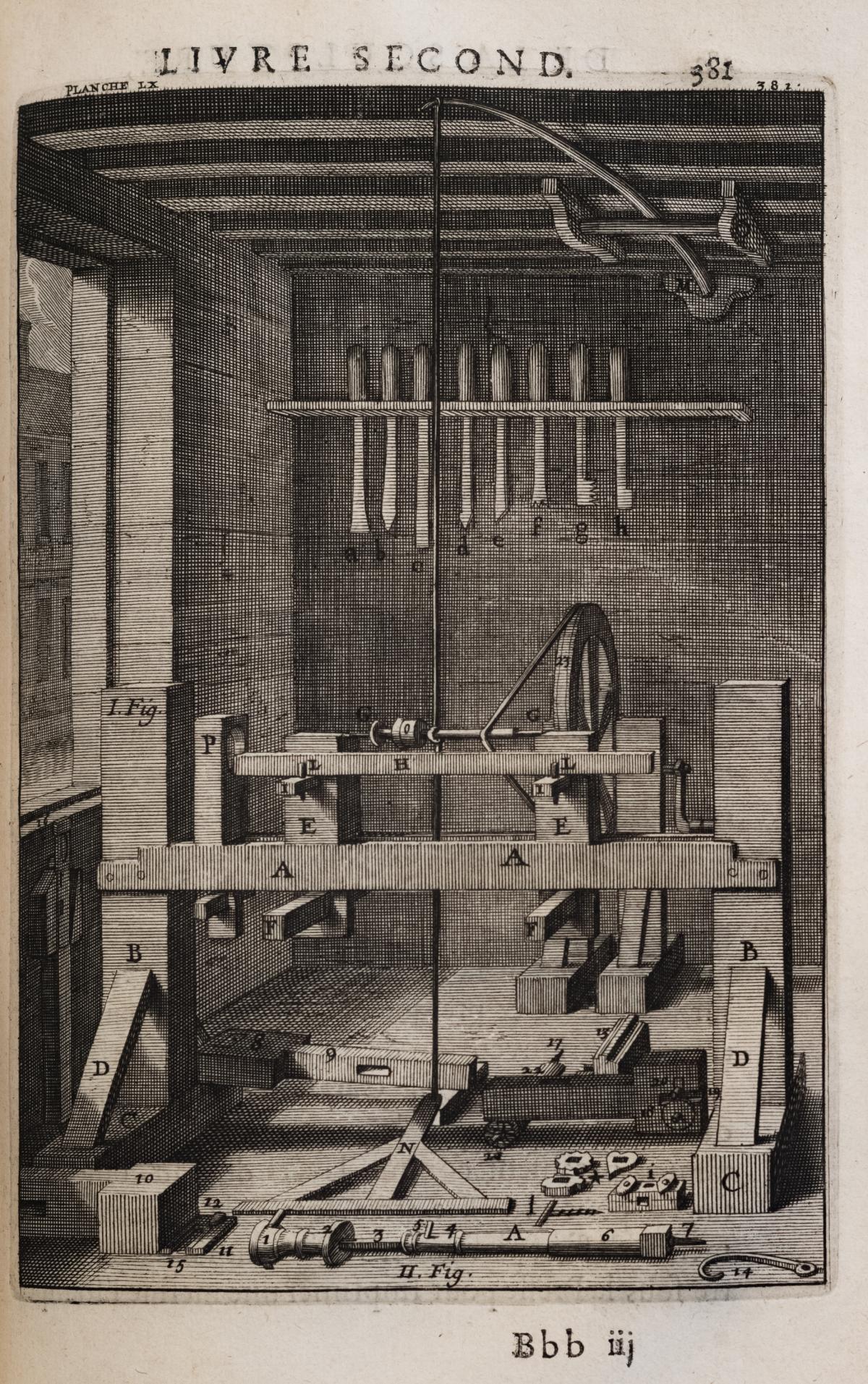

Hulot, pere "L'Art du tourneur mecanicien" 1775

Hulot, pere "L'Art du tourneur mecanicien" 1775Prior to the Industrial Revolution, the two most common styles of lathes were pole lathes and great wheel powered lathes. Pole lathes featured a string looped around work held between centers. One end of the string was fastened to a springy wood pole and the other was attached to a pedal. The turner would press down on the pedal and the work would rotate in one direction. The work would be cut and then the turner would let up on the pedal so that the pedal would be pulled up, rotating the work in the wrong direction, and concurrently resetting the string for the next cut. This method worked well -- and a pole lathe was very easy for a capital-deprived turner to afford. The image above features a pole lathe in action at a French shop for wood and ivory turning. Interestingly, while the person in the back is sawing out stock, two people, one looking pretty young, are roughing out stock before it gets turned. Pole lathes work with an interrupted motion, and rounding the stock saves oodles of time. The lathe itself, with a springy pole attached to the ceiling, was pretty standard. This image from 1775 isn't the earliest image of turning, but it is representative (and also makes for a great opening picture for this blog post).

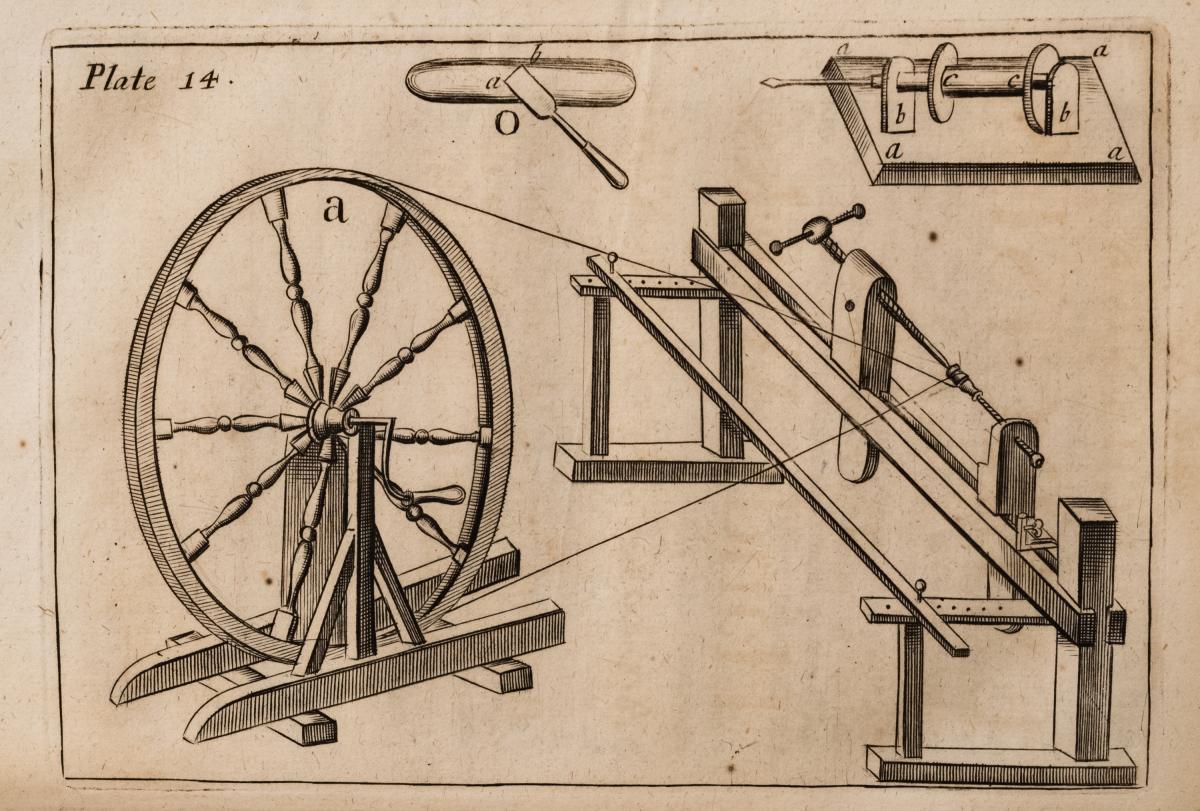

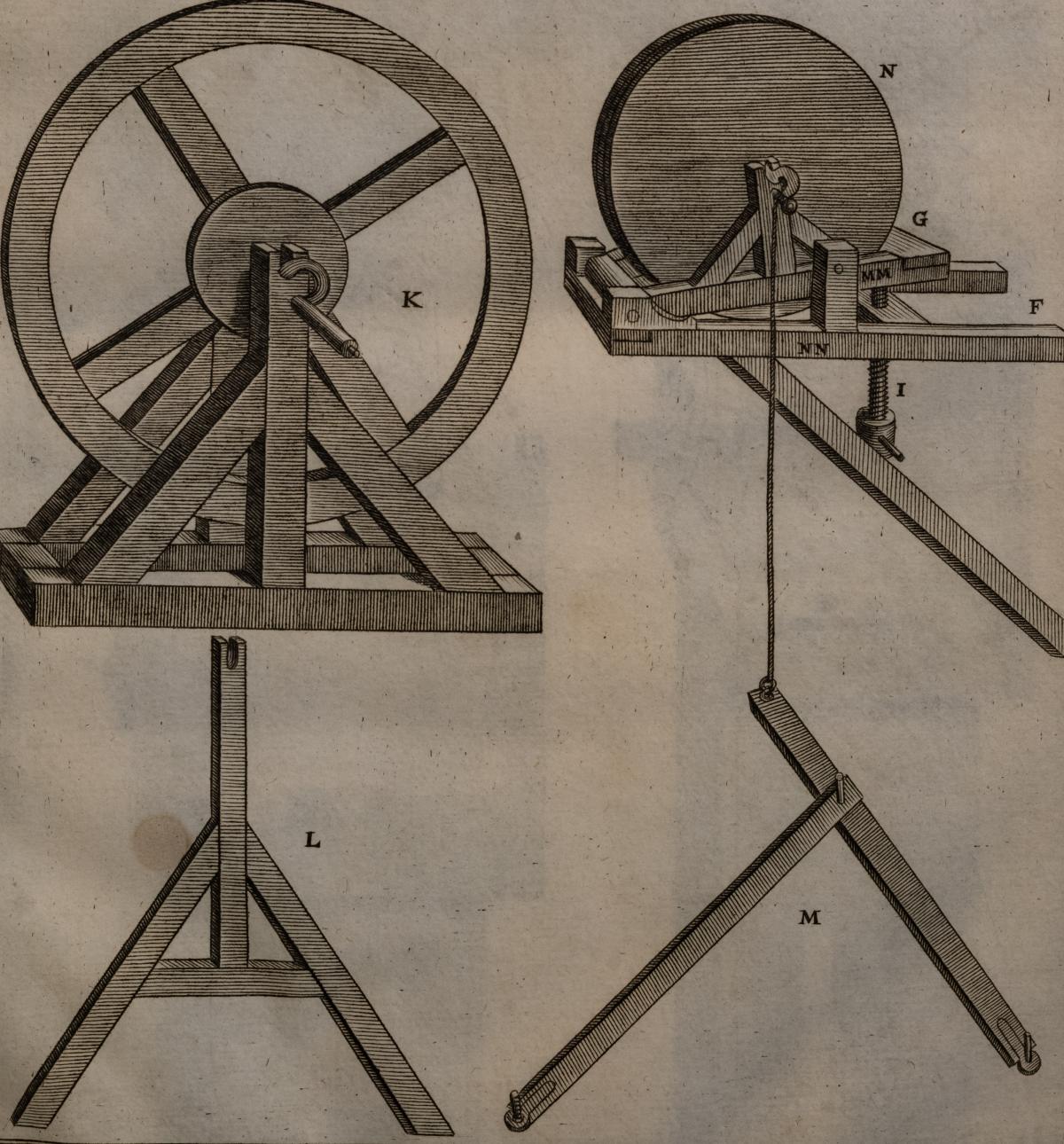

Joseph Moxon's "Mechanick Exercises" 1680

Joseph Moxon's "Mechanick Exercises" 1680The second way of powering a lathe was using a great wheel (as in the picture above). A large wheel - as large as the turner had space for - was mounted in line with the lathe and connected with a string belt. A second person turned the wheel, powering the lathe while the turner cut wood. This model worked very well, giving the turner continuous motion, but had the downside of requiring a second person's involvement.

At the time of the picture (1680) water and water mills could have been used to gear up a wheel to power a lathe, as it was used for all sorts of larger machinery. I do not know know of a specific case where this occurred, and I am not sure if the mechanics at the time were precise enough to drive a line-shaft fast enough to be practical for a lathe.

Many permutations of the pole and great wheel lathes existed. The spring of the pole could be replaced with a bow, and all of the early books on lathes show pole type lathes with small crankshafts on the ceiling which could be pumped by a second person with the cord attached to the crank.

The main problem with a pole lathe was the interrupted rotation. The main problem with a great wheel lathe (and its derivatives) was the need for a second person. You could, I suppose, also use a treadmill apparatus for an animal, but I haven't found any examples of lathes being powered in such a way.

There exists a drawing from 1480 by Leonardo da Vinci that shows a treadle lathe. Was it something he saw, dreamed up but didn't build, or actually built what he designed? There is no proof one way or another for any of these options. The earliest image I have of a treadle lathe dates from 1680 and appears in Joseph Moxon's "Mechanick Exercises." That might be the first published image of a treadle lathe in literature, but I'm not sure. Considering how many pages are devoted to pole lathes and great wheel lathes in the few lathe books that exist from the 17th and 18th century, you have to make an assumption that treadle lathes were not that common. Moxon shows the treadle (below) on a special lathe for oval turning. It's doing fairly light work, but Moxon says that the treadle is useful for turning oval work, as is a great wheel lathe, because you needed continuous motion.

Joseph Moxon's "Mechanick Exercises" 1680

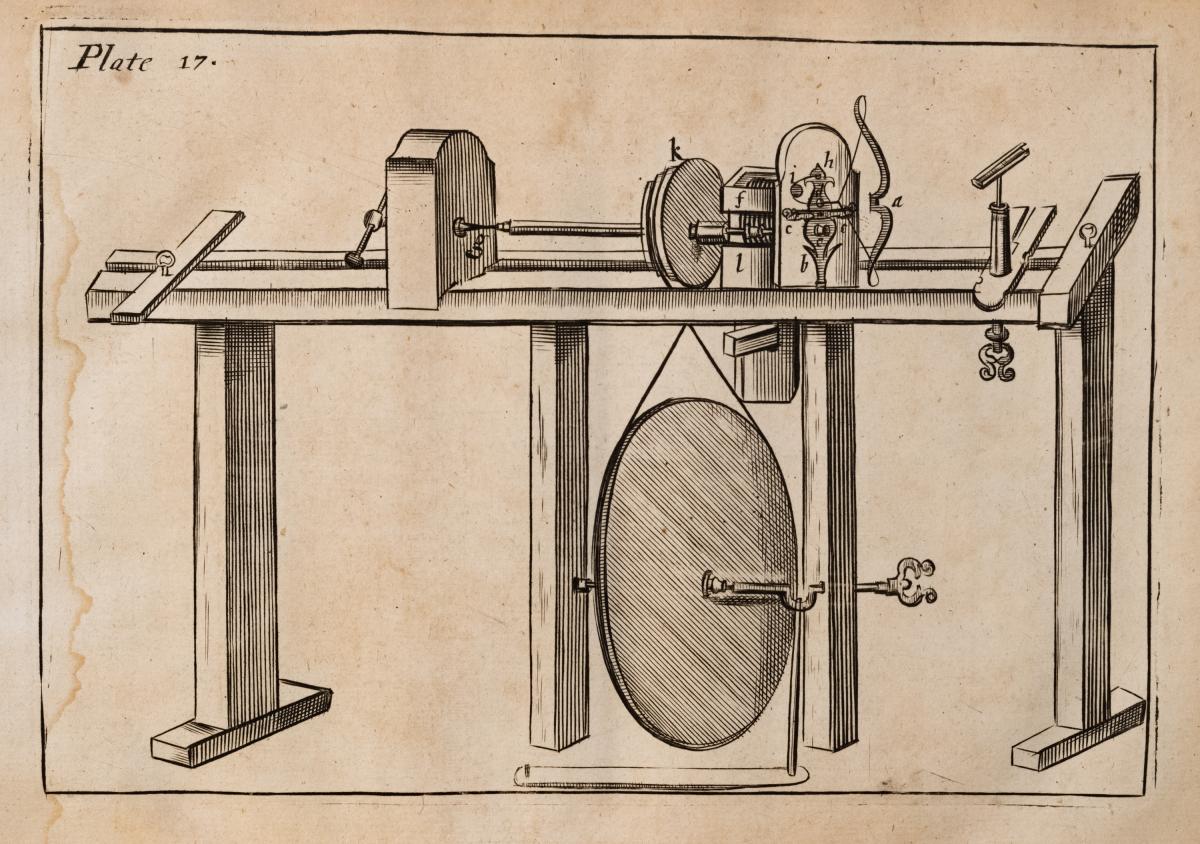

Joseph Moxon's "Mechanick Exercises" 1680  Charles Plumiers "LArt de Tourner" 1701

Charles Plumiers "LArt de Tourner" 1701Plumier, writing in France in 1701, has drawing upon drawing of pole lathes, great wheel lathes, overhead drive mechanisms. The first illustration in his book is of a large lathe which has an overhead hand cranked wheel and a pole option. But a few pages later, a large illustration (above) of another main lathe shows the same hand-pumped flywheel mounted on the ceiling as before - but no spring pole option. Later in the volume, he detailed the parts of this lathe, and the detailed drawings shows something interesting.

Charles Plumiers "LArt de tourner" 1701

Charles Plumiers "LArt de tourner" 1701Whereas in the main drawing the pull cord for the flywheel is clearly meant for hand action, the drawing above shows how to connect the flywheel on the ceiling to a floor pedal. As near as I can see from the drawings, the flywheels are just heavy wheels of solid wood and would work but are pretty light for a general purpose lathe. This is a big deal. Part of the advantage of a flywheel is that the flywheel stores energy and evens out the footwork so the lathe is powered all the time, not just on the downstroke of the pedal. The pedaler might be coasting on the way up, but the lathe is still drawing power throughout the entire stroke.

Later in the book, Plumier shows a light duty treadle lathe. This makes sense: a lot of the fancy work Plumier described required continuous motion and many of his readers were hobbyists who would want to work alone.

But these circumstances changed. By 1800 (and certainly by 1840), treadle lathes became all the rage - from the high end of Holtzapffel, to random low-end lathes for homeowners and hobbyists. I found many advertisements for these lathes. If you were a small shop or a hobbyist, the treadle lathe was the way to go. Great wheel lathes disappeared and factory line shafts appeared in mills. Pole lathes remained in use at least until the middle of the 20th century by bodgers working in the forest, where it was easier to turn chair parts in the forest then haul out raw wood.

What changed?

What happened?

It's easy to point to the nature of invention, to say that things have to be invented piece by piece by piece by piece. And the treadle is a natural evolution for small lathes. But I don't think that's the real case. If you're in a production environment, a great wheel lathe allows you to have continuous turning - as long as you have someone to do the powering. With the overhead drive motion seen in Plumier and Moxon and even earlier in Felibien (below), a turner could be very productive cranking the overhead crank if you had somebody else helping. In a production environment, a great wheel made a lot of sense. Pole lathes made a lot of sense as well because they entailed very little capital to build one, and they worked well for a one-man shop. Moxon's treadle lathe is a dainty little thing, with Plumier is not far behind. Plumier's overhead flywheel powered by a treadle could be operated by one person. The wooden flywheel could be big and store more momentum, but it would far from ideal. Plumier also illustrates a fairly lightweight treadle lathe, but it had a wooden flywheel.

I think the key is that there's a technical problem with all treadle lathes before 1780. The flywheels that you see in Moxon and Plumier are of wood - and they are simply not heavy enough. Holtzapffel tells us that the flywheel should weigh anywhere between 30lb and 100lb (for a big metal turning lathe). The flywheel also has to be machined and balanced, otherwise the entire lathe would shake and wobble. The cast iron flywheel on our treadle lathe weighs about 30lbs. But the operative word is cast iron. Cheap cast iron is an 18th century invention, and the ability to machine the grooves easily is a very late 18th century invention. While a great wheel lathe can be huge and made of wood, it gets its momentum from its diameter, not its weight. A treadle flywheel that has to live under a lathe bed and has a maximum diameter. It gets its momentum from mass. While it was certainly possible, even in the 16th century, to make a heavy bronze flywheel, accurately machining and boring it would be very difficult before 1800. And if the flywheel isn't machined, it's useless.

Up until the late 18th century it was possible, but very difficult, to can make a balanced cast flywheel except on a onesie-twosie basis, so it wasn't until the 19th century that machining a cast iron flywheel was cost-effective.

We actually tested a wood flywheel in an early prototype of the lathe. It worked, but not as well as the same same flywheel did when we bolted some metal plates to it. There are of course tradeoffs in weight, and some basic physics involved. If you have a light flywheel, the lathe is easier to start and spin, but it doesn't hold a lot of momentum, so heavy cuts slow it down a lot. If you have a heavy flywheel, the lathe is hard to start and you have to pedal for a few seconds to get it up to speed, but then it can power through work and its overall performance is better. In other considerations, a heavier flywheel is harder to move around, and it and costs more. Flywheel design is a compromise between usability and cost.We thought the learning curve would be easier with a cast iron flywheel, ideally in the sweet spot of a good bit heavier than a wood one, but on the lighter side of the weight range.

Incidentally, there's almost no literature on the design of treadle lathes. Part of the interest fueling this project for the past 3 years has been understanding the engineering why something was done and then actually testing it out - i.e., reinventing the wheel.

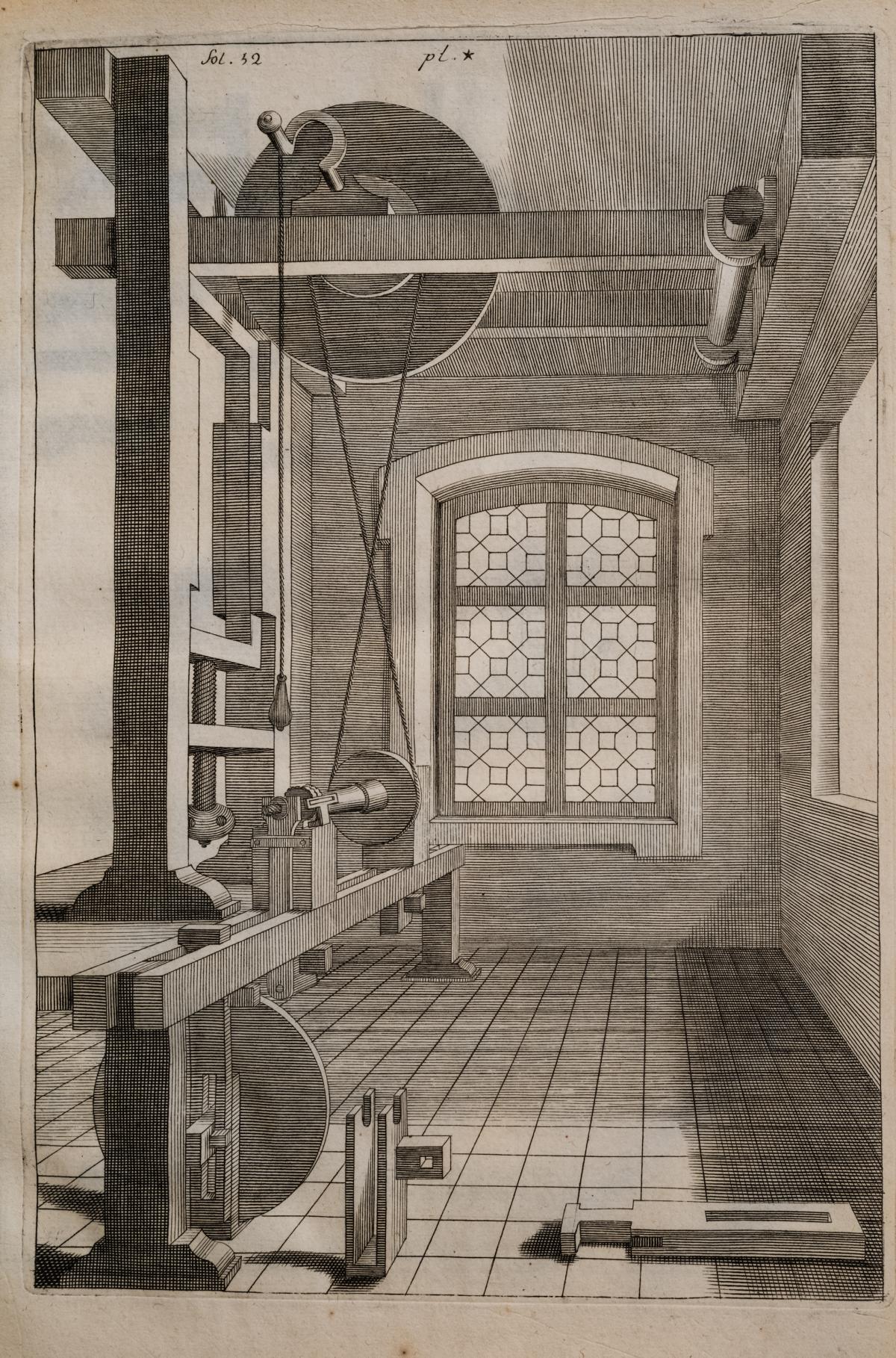

The drawing of a treadle-powered grinder (below) from Hulot is interesting. Chronologically, Hulot is later than the other references in this blog. The book published in 1775, with parts written very significantly earlier than that. But the grinder, unlike the traditional pole turning lathe at the start of this blog, is high tech. I can't tell if the flywheel is metal or not, but it looks metal to me, and in 1775 or earlier making it would have been quite a trial.

Lastly, Flibien's book is slightly earlier than Moxon's, but the lathe is nearly identical to the other lathes shown here. And we have the combo power option of pole or wheel. I originally thought that this was a drawing convention with a weird perspective, but I wonder if having a pole made it possible for one person to do pretty heavy turning, but having a wheel option allowed for faster, lighter work, if a second person were available to pump. (Lighter work because it's a wooden flywheel)

Hulot, pere "L'Art du tourneur mecanicien" 1775

Hulot, pere "L'Art du tourneur mecanicien" 1775  Andr Flibien "Principes de l'architecture, de la sculpture, de la peinture, &c." 1676

Andr Flibien "Principes de l'architecture, de la sculpture, de la peinture, &c." 1676 record breaking blizzard.........